- Optical working platform on a computer

- Laser cavity analysis and design tools

- Teaching tools

Optical work platform on LASCAD computers

Although LASCAD offers complex engineering tools, one of its basic principles is to create an easy-to-use program. It provides a programmatic user interface that acts as an optical workbench on a PC for the intuitive design of laser resonators. This allows people to learn about the results of experiments in the lab or at an exchange meeting without having to spend a long time reading complex instruction manuals or typing in large numbers:

- Optical elements such as planar mirrors, lenses, or crystals may be added, merged, pulled, adjusted, or eliminated with a mouse click

- The phenomenon of dispersion of resonators and crystals is fully considered

Finite element analysis, ABCD matrix and wave optical encoding can be selected from the menu bar

LASCAD Laser Cavity Analysis and Design Tool

Finite Element (FEA) for Thermal Effects

Analytical FEA can be used to calculate temperature distribution, deformation, stress, and mechanical fracture of laser crystals. The calculation process needs to consider the parameters of the material, the pump configuration and the cooling structure. FEA is a well-known numerical method for solving difference equations, such as heat transfer equations, in the field of technical physics. Although FEA is widely used successfully and is an indispensable method in many other areas of engineering, it has not yet been implemented on any other commercial laser design software.

In order for FEA to be directly applied to the design of laser cavities, LASCAD® pre-designs FEA models for important configurations, such as rod, strip and disc lasers pumped on the end face or side. A variety of materials or doped crystals also have relevant models, such as unopeded end mirrors. Users can customize dimensions, FEA meshes, boundary conditions, and other parameters in the model. Temperature-dependent material parameters can also be added to the model by analytically.

The absorbed pump power density distribution is characterized by an analytical approximation expression based on the super Gaussian function. To enable numerical modeling of absorbed pumped light, LASCAD® supports importing data from ZEMAX and TracePro’s ray tracking programs. These programs generate three-dimensional data of the absorption pump power density, which can be imported directly into LASCAD?. ZEMAX and TracePro are useful for pumping light distribution when simulating flash pumps or unconventional pump structures.

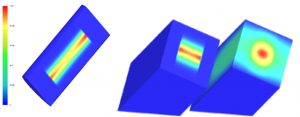

LASCAD provides an open graphics language that visualizes the distribution, boundary states, and FEA results of pumped light using sophisticated 2D and 3D graphics tools.

ABCD Gaussian beam propagation code

LASCAD provides an open graphics language that visualizes the distribution, boundary states, and FEA results of pumped light using sophisticated 2D and 3D graphics tools.

The results of FEA are applied to the ABCD transport matrix, temperature distribution, and temperature-dependent refractive index function for parabolic fitting in the vertical optical axis direction. During fitting, the finite element mesh is further divided along the crystal axis and vertical direction. The same method can be used to complete the fitting of the crystal end face deformation. For many structures, such as a crystal rod pumped by the end face, the above fitting approximation can obtain a reliable solution of the laser mode.

Reliable solution to laser mode. To see the results of the ABCD transmission matrix, the base mode spot size along the axis of the cavity and the Ermi-Gaussian polynomial of the higher-order module are displayed. Inside the crystal, the superposition between the pump light and the laser transverse mode can also be displayed directly. To account for the effects of dispersion, calculations are performed simultaneously with two planes perpendicular to the cavity axis.

For standing wave cavities, graphs can be obtained based on the stability of the resonator that produces the g-parameter.

Calculating the laser power output can be calculated from the Gaussian beam model and the density of the absorbed pump power, while facilitating the analysis of the transient processes of the CW laser and the laser.

The overlap of the laser model with the pump beam can be intuitively seen through the axis of the crystal

Physical optical methods

In the case of parabolic approximation and ABCD transmission matrix accuracy is not sufficient, the results of FEA can be imported into the physical optical code for high-precision calculations. Physical optical methods can provide panoramic three-dimensional simulation of the propagation of a beam in a crystal without parabolic approximation. To this end, the physical optical method employs a step-by-step beam propagation method (BPM) to simulate the propagation of the beam in small steps in crystals with thermal distortion. During the calculation, BPM takes into account the local refractive index distribution obtained in the FEA analysis and the crystal end face deformation. Using the Fox-Li iteration, the BPM method calculates the multiple round-trip transmission of the beam in the resonator, and finally converges on the base mode or the superposition of multiple higher-order transverse modes. During the calculation there are two graphical windows that are open, one showing the light intensity distribution on the output mirror as the number of iterations increases, and the other showing the dimensional convergence process of the spot and the output power calculated synchronously as the iterations in the resonator proceed. In addition, you can open a window showing the quality of the beam. The BPM method can also perform the calculation of intrinsic spectral lines in the cavity and the shape calculation of the eigen-transverse module.

Given the limited size of the light bar and cavity mirror, the BPM tool also takes into account the dynamic characteristics of the gain as well as the diffraction effect, so that it is closer to the actual situation than the DMA calculation. Another important feature of BPM is that it can simulate the effects of cavity offset.

Laser transient characteristics

To analyze the transient characteristics of lasers, LASCAD® provides dynamic multimodal analysis (DMA) tools for multimodal and Q-modulated operation. To this end, LASCAD uses the finite element solving tool to solve a time-dependent system of velocity equations that contain equations that describe the number of photons for each mode (predefined Gaussian lateral eigenmode). This approach can provide details of pattern competition, power output, beam quality, and pulse shape (see LASCAD Tutorial 4: Dynamic analysis of multimode competition and Q-Switch operation (PDF)). The simulation results were shown to match the experimental measurements very well (see “Dynamic multimode analysis of Q-switched solid state laser cavities” (PDF))

Dynamic Pattern Analysis (DMA) can provide the following important features:

1. Laser output pulse shape and output power change curve over time during high-frequency or single-pulse Q operation.

2. Adjust the output power of different horizontal modes of the laser during Q or CW operation.

3. The beam distribution curve is calculated as a superposition of a single horizontal mode.

4. Adjust the beam quality factor M2 of the laser when Q or CW is running.

5. Effect of hard edges and Gaussian light bars on beam quality.

6. Gaussian and super Gaussian reflective output mirrors.

LASCAD Laser Teaching Aids

Although LASCAD was primarily developed for laser engineering, its easy-to-operate user interface makes it ideal for teaching and training scientists and engineers. The basic principles of Gaussian beams can be learned during use, and complex resonator structure configurations, including thermal lens effects, light bars, Q adjustments, etc., can be clearly demonstrated.

LASCAD results validation and outlook

University of Kaiserslautern, Germany. The laser team led by Professor Wallenstein has been using this software for many years to analyze, design, and optimize high-power diode-pumped lasers with composite crystals. Their series of experimental measurements have verified that the accuracy of the simulation results is very high, see Figure 6. LAS-CAD is currently involved in a government-supported research project: Simulation and Optimization of Innovative Laser Systems. In this project, LAS-CAD works with 7 German laser manufacturers, The University of Erlangen, Germany

Gutingen Laser Laboratories and others collaborated to develop new numerical simulation tools for resonators. One of the latest collaborations is the DMA already mentioned earlier. The numerical results obtained by the DMA simulation have been experimentally verified by the German company Inno Las, see the dynamic multimode analysis of Q-switched solid state laser cavities in Optics Express, Vol. 17,17303 -17316 (2009)。Another research goal of the project is to develop a FEA method that provides a dynamic three-dimensional solution to the electromagnetic field equations in the resonator. Preliminary results have been published in Photonics West 2009, see Fine element simulation of solid state laser resonators in Proceedings of SPIE Vol. 7194-16 (2009)。